- Markets

- Products

- Services

- News

- Tools & Resources

- About Nexans

- Search

- Contact us

- Compare

- Sign in

Transforming future rail transport

The Promise of High-Temperature Superconducting Cables

Maintaining the resilience of passenger and freight operations is a priority for railway infrastructure managers and train operators.

Railways are major electricity users. In Europe, approximately 55% of the rail network is electrified and this portion carries 80% of traffic. Electricity used at the point of consumption by trains – traction power – is provided at a range of voltages, depending on geography.

Common voltages include 25kV AC, 15kV AC, 1,500V DC and 750V DC. Reliable electricity supplies are also mission critical for signalling systems, and for station equipment, such as escalators, ventilation and lighting.

increase in the demand for electricity by 2030 (source: International Energy Agency)

rail network is electrified

passenger rail acitivy by 2050 (Source: IEA)

Superconductivity to help overcome rail industry challenges

The rail industry faces great challenges that could be overcome by extending the use of groundbreaking technologies like superconductivity, which is besides part of the IGTs (Innovative Grid Technologies – supported by CurrENT, a key industry association representing innovative grid technology companies operating in Europe).

More about CurrENT and Innovative Grid Technologies::

#1. Modernization of railway infrastructure involves refurbishing the infrastructure and enhancing network reliability, which are key challenges for network operators

Strengthening lines, increasing speeds, accommodating more trains, and thereby improving capacity and mitigating carbon footprint, require infrastructure improvements, particularly in densely populated areas. This includes track regeneration and geometry adjustments, upgrading the overhead contact system, constructing passing loops, replacing level crossings and pinch points, and alleviating congestion at junctions.

Superconducting DC cables and superconducting fault current limiters (SFCL) are currently contributing to the modernization of railway systems and subsequent to Net-Zero programs. The French National Railway Company (SNCF Réseau) announced several projects where superconductivity will play a critical role, including efforts to regenerate traction power, increase the power availability on their rail network and expand the deployment of SFCLs to enhance networks’ reliability.

Some recent examples on how superconducting systems can contribute to rail efficiency:

- The superconducting MagLev and the Chuo Shinkansen, which connect Tokyo and Osaka at a speed of 505 km/h in just 67 minutes (438 km), have now become a reality.

- Gare de Montparnasse SuperRail project in Paris will ensure 16 trains can be operated at the same time thanks to the superconducting cable systems powering up the current network.

- In Bussurel city, the railway network will achieve unprecedented continuous operational performances thus ensuring a better control of network stability and further contributing to an increased train punctuality All these benefits were made possible thanks to SFCL (Superconducting Faut Current Limiter).

A perfect illustration of these benefits is the SuperRail project which is co-funded by the French government under the France 2030 program. This pioneering project demonstrates how superconducting cables can improve power availability and reduce costs.

A perfect illustration of these benefits is the SuperRail project which is co-funded by the French government under the France 2030 program. This pioneering project demonstrates how superconducting cables can improve power availability and reduce costs.

#2. Sustainability and performance : combining efficiency with environmental responsibility whilst ensuring economic sustainability and performance

Rail fosters green mobility with its environmental benefits, addressing sustainability, mass transit and freight challenges. As a greener alternative, the rail freight industry can replace over 100 trucks with one freight train, significantly reducing carbon emissions and contributing to tackling climate change. Building a sustainable rail industry requires considering environmental, social and economic factors.

Superconductivity is currently advancing industrial applications, offering significant potential to transform rail networks. By incorporating superconducting cables and fault current limiters, the rail industry can attain exceptional levels of efficiency, capacity and sustainability. This progress aligns with global objectives for decarbonisation and fosters an energy transition.

Furthermore, high-temperature superconductivity offers significant cost reductions. Numerous projects have demonstrated millions of euros in savings by decreasing capital expenditures compared to conventional copper or aluminium cables. Although the savings are contingent upon project location and complexity, HTS technology helps overcome permitting right-of-way challenges, enabling efficient high-voltage transmission at medium voltage levels. As copper and aluminium become increasingly scarce and expensive, the return on investment for HTS technology will improve.

Upgrade and secure rail power supply

Superconducting solutions

Superconductivity is increasingly being utilized in industrial applications with notable potential to reshape and revolutionize power transmission including rail networks. Through the adoption of superconducting cables and fault current limiters, the rail industry stands to enhance efficiency, increase capacity, and promote sustainability. These advancements align with global decarbonisation objectives and facilitate the transition towards more efficient energy systems.

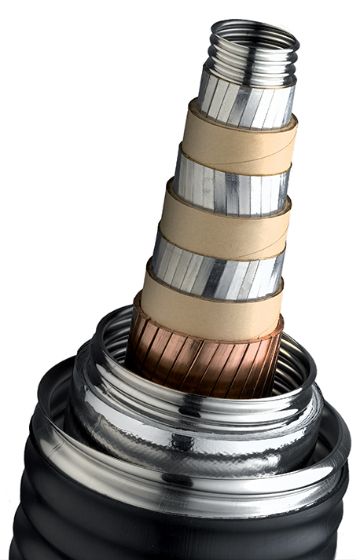

High-Temperature Superconducting (HTS) cables can carry significantly higher currents with virtually no electrical resistance. This means they can deliver up to 10 times more power than conventional copper cables of the same size — without the heat, loss or bulk.

Superconducting cables offer a breakthrough

Reliance on single points of grid supply increases the risk to railway operations in the event of a failure at an electricity substation. Adding new feeders using conventional cable technology can be disruptive and prohibitively expensive, particularly in cities. HTS cables overcome this problem, making it possible to deploy new feeders in narrow rights of way.

HTS cables can also be used for distribution within the railway network. This makes it possible to transmit power at the railway’s native operational voltage – even if this is a relatively low voltage – over long distances and at a high current, reducing the need for substations on railway premises. The small dimensions of HTS cables and the fact that they produce neither heat nor electromagnetic fields means that it is possible to accommodate superconducting cables within narrow trackside corridors.

HTS cable systems allow for sustainability and performance : combining efficiency with environmental responsibility whilst ensuring economic sustainability and performance

The high current density, which can be transmitted in a comparatively small cross-section, makes it possible for the cable routes to be significantly narrower with the same capacity. The line width is a very important issue in the construction of power lines for several reasons. For example, it is often not possible to retrofit or upgrade conventional routes in conurbations due to space constraints, but a superconducting route can be realised due to its small space requirement. This was demonstrated as an example in the SuperRail project - this project illustrates perfectly how their compact nature enables them to transport very high power through a limited space.

More about SuperRail project:

“ Superconducting cables can transmit significantly more power than conventional ones, 3 to 5 times in AC systems and up to 10 times in DC systems, at similar or lower voltage levels with equivalent land take ”

- HTS cables systems provide unparalleled transmission capacity : they can transmit 8-10x the power (in the same footprint, technology available from LV 400V @2000A to MV & HV 230kV @4500A),

- x200 current density of 2G HTS ribbons in liquid nitrogen (70 K = −203.15°C) compared to conventional resistive cables

- At low voltage, 1 HTS cable can distribute 400-680V @6-10kA

- Transmission (HV) at distribution (MV) voltage level with no electrical losses

- Minimal electrical loss in AC while zero loss in DC

- No electro magnetic field

- Space saving: less physical space is needed for cable trays, ducts, and conduit systems. As railway stations are often located in urban areas, reducing their footprint lowers land requirements and CAPEX.

- Minimal land take and optimized costs: HTS cables require less land and lowers construction costs due to its smaller footprint compared to conventional cables. This reduces civil works, shortens project timelines, and minimizes environmental impact for a more sustainable solution.

- Complexity reduction and enhanced profitability : HTS cables can allow data centers to use MV power instead of HV power, reducing the complexity and time for permitting and rights-of-way. This enables earlier facility operation, providing services sooner and generating a faster return on investment.

Direct Current and Superconductivity: a powerful combination for loss-free power distribution

A growing trend in modern electrical infrastructure is the shift toward Direct Current (DC) transmission and distribution, particularly in environments where energy efficiency and power quality are paramount—such as offshore wind, data centres, rail systems and large-scale industrial facilities.

Superconducting cables, especially High-Temperature Superconducting (HTS) systems, offer a strategic advantage in this transition. When paired with DC systems, HTS cables can deliver electricity with zero electrical loss, enabling a new standard of efficiency and performance.

Under conventional conditions, electrical transmission typically incurs 3–5% energy losses due to the resistivity of copper or aluminum cables and the multiple conversion stages in AC and between AC and DC. These losses increase with distance, voltage drop, and current density —adding up to significant inefficiencies in large-scale systems.

In contrast, HTS DC cable systems eliminate resistive losses, regardless of current level or cable length. This makes them ideal for high-capacity, long-distance transmission, as well as dense urban environments and mission-critical infrastructure like hyperscale data centres.

Key advantages of HTS in DC applications include:

- Loss-free transmission across High Voltage (HV), Medium Voltage (MV), and Low Voltage (LV) networks.

- Reduced energy consumption, improving sustainability and lowering operating costs.

- Smaller footprint, enabling compact installations in constrained spaces.

- Higher reliability, with reduced heat generation and simplified cooling requirements.

A pioneering example of this technology in practice is the world’s first HTS DC cable system deployed by SNCF Réseau at Gare Montparnasse in Paris, France. This installation demonstrates how superconducting DC systems can modernize critical infrastructure by enabling higher capacity, lower losses, and more efficient energy use.

“ Superconducting cables need to find their place in an LVDC environment. These conductors, with zero resistance, allow transmission of up to 10 times more power in the same space. ”

Protection & power conditioning

Protection and Power Conditioning: enhancing resilience with superconducting fault current limiters

An important but often overlooked advantage of superconducting technology is its role in electrical protection—specifically through the use of Superconducting Fault Current Limiters (SFCLs). These devices significantly enhance power quality, system resilience and operational safety of energy infrastructures.

In the event of a short circuit or fault condition, SFCLs instantly and automatically limit excessive current without the need for mechanical intervention. Unlike conventional protection devices, which rely on opening a circuit to interrupt current flow, superconducting fault current limiters use the intrinsic properties of superconductors to transition rapidly from a superconducting (zero-resistance) state to a resistive state. This transition happens within milliseconds, allowing SFCLs to absorb and limit the fault current before it can damage downstream equipment.

This capability provides several key benefits for the rail industry:

More information about superconductivity:

- Improved network reliability and safety: the SFCL acts as a shock absorber in the event of a problem, limiting current peaks and disruptions to the network when short circuits occur.

- Optimized infrastructures: longer term, the SFCL could pave the way for smaller electric traction installations, thereby cutting rail infrastructure costs, while supplying power for more trains.

- Better service: the SFCL avoids the need for rail works that are inconvenient for users, providing an efficient, cost-effective solution with no impact on the traffic schedule.

In the context of hyperscale and gigawatt-scale facilities - where electrical disturbances can have significant operational and financial consequences - SFCLs offer a smart, scalable solution that supports 24/7 reliability, self-healing electrical infrastructure and reduced maintenance requirements.

In short, integrating superconducting fault current limiters into the power architecture provides a modern, automated approach to protection and conditioning.

More information about superconductivity:

Enabling the next generation of rail transport

Driving sustainability in rail transport

Electrification lies at the heart of sustainability in rail. Currently, the approximately 50% of current global rail energy use comes from electricity (International Union of Railways (UIC) ). This transition, coupled with the integration of renewable energy sources, is a game-changer for emissions reduction. The rail industry is turning to solutions that will contribute to more energy savings and sustainability of rail infrastructures, enabling better power distribution and data/signal transmission with minimal energy losses whilst ensuring safe operations.

Superconductivity, previously limited to research settings, is increasingly being applied within industrial contexts, offering significant opportunities to transform rail networks. The integration of superconducting cables and fault current limiters enables the rail sector to enhance efficiency, increase capacity, and support sustainability objectives, thus contributing to global decarbonisation efforts and the broader energy transition.

The rail industry can benefit from this technology to modernize its infrastructure

- Innovation as the backbone of railway development: the integration of superconductivity will modernise infrastructure and boost network reliability.

- Superconductivity - enabling fossil-free mobility: The declining availability of fossil fuels highlights the need for sustainable alternatives, with rail positioned as the backbone of green mobility.

- Sustainability and performance go hand in hand: Superconducting technologies offer a unique opportunity to combine efficiency, environmental responsibility, and economic viability.

As global energy systems shift toward electrification and decarbonization, the rail industry must align with the principles of the energy transition. HTS technology directly supports this trajectory by:

- Reducing grid losses

- Enabling more efficient integration of renewable energy sources

- Supporting compact, modular, and resilient infrastructure design

All these programs and the history of Nexans position the company today as a global leader in superconducting cables for electrical grids. This makes Nexans the first European and global industrial player to possess the technology ready to meet all the needs of data centre applications. In other words, for HV, MV, and LV cables, Nexans is currently the only manufacturer worldwide capable of meeting all these needs, while offering a solution to the energy sector seeking to improve infrastructure capabilities.

More about Nexans High Temperature Superconducting (HTS) Solutions:

Our websites

Select your country to find our products and solutions

-

Africa

- Africa

- Ghana

- Ivory Coast

- Morocco

- North West Africa

- Americas

- Asia

- Europe

- Oceania