- Markets

- Products

- Services

- News

- Tools & Resources

- About Nexans

- Search

- Contact us

- Compare

- Sign in

Nexans CRYOFLEX® joint-free transfer lines to support degausing systems for Allied Navies

-

LOCATIONUS

-

PARTNERSHIPAllied Navies

-

MarketCryogenic & Superconducting Systems

Context

What is degaussing ? and why is it needed ?

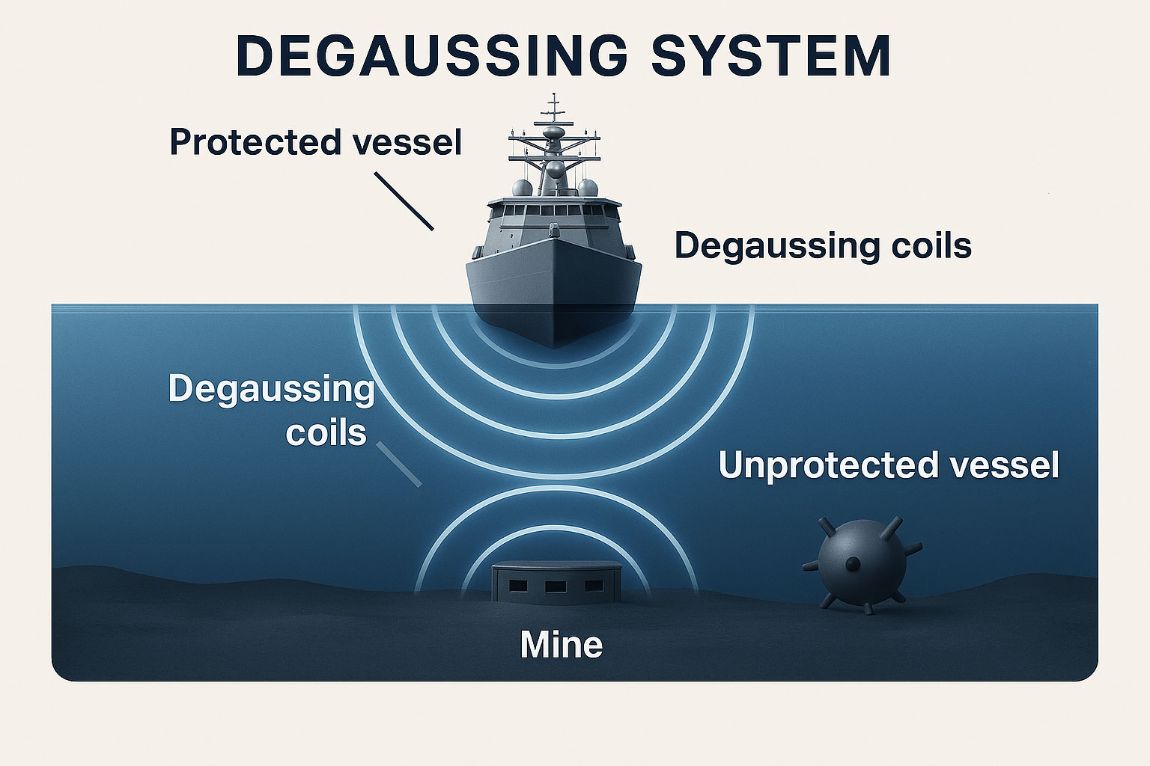

A steel-hulled vessel generates a substantial magnetic field, effectively functioning as a large floating magnet. As the ship crosses water, its magnetic field interacts with and can either augment or diminish the Earth's natural magnetic field. Due to these distortion effects, the ship can activate magnetically sensitive ordnance or detection devices calibrated to identify such variations.

When a ship is constructed within Earth's magnetic field, it acquires a certain level of permanent magnetism. The extent of a ship’s induced magnetization is determined by both the intensity of the Earth's magnetic field and the vessel's orientation relative to this field. Degaussing aims to neutralize a ship’s magnetic field so the surrounding area is unaffected by its presence.

Degaussing involves the installation of electrical cable systems around the circumference of a ship's hull, extending from bow to stern on both sides. A controlled electrical current runs through these cables to neutralise the ship's magnetic field. The degaussing system is installed on ships to minimize their impact on the Earth's magnetic field. To achieve this, electric currents are adjusted in degaussing coils placed inside the hull to neutralise changes in the Earth's field around the ship. This, in turn, decreases the likelihood of detection by magnetically sensitive ordnance or devices. The ship’s permanent magnetization constitutes the primary source of its persistent magnetic field.

Ships moving through the earth’s magnetic field creates a magnetic disturbance that is detectable by enemy magnetic mines. That’s where degaussing coils play a key role by generating a magnetic field to mask ship’s magnetic signature. However as magnetic sensors become more accurate, effective degaussing requires a higher percentage of the ship’s signature to be masked thus meaning more degaussing cables.

Challenges and solutions

One of the world's largest navies decided to innovate by adopting an onboard degaussing system based on superconducting coil technology. However, the engineering work carried out on three ships proved difficult to implement, facing a series of challenges:

- Much better ship modeling needed (magnetic)

- Degaussing loops were required in all three ship axes which proved very heavy and expensive to install

- Must be an active system

- Earth’s field different depending on position

- Requires input from ship GPS

The various studies eventually demonstrated that the challenges in developing advanced degaussing could be overcome using the cable system that could significantly reduce the magnetic signature of ships. However, a final obstacle remained: the weight of the conventional cable system that clearly penalised the solution, leading the Navy to seek additional solutions to reduce the weight of the onboard system.

The solution: AMSC High-Temperature Superconducting system integrating AMSC HTS Wires and NEXANS CRYOFLEX® TRANSFER LINES

That’s where HTS came into effect: replace Heavy Copper Cables with Lightweight HTS. Why?

- Significantly reduces cable weight

- Flexible and small enough to use conventional degaussing conduit

- Can carry current of multiple copper cables in one HTS cable, leading to reduced install cost

However, one remaining challenge was also to be able to provide long length, low heat leak, flexible cryogenic cable housings durable enough to survive Navy qualification testing (shock, vibration, EMI) and reliable enough for long term ship board service.

The solution: AMSC High-Temperature Superconducting system integrating AMSC HTS Wires and NEXANS CRYOFLEX® TRANSFER LINES

More information about Nexans CRYOFLEX® transfer lines:

- High Electrical Capacity and Low Weight solved via AMSC’s Amperium HTS wire - high current density, light weight

- High cryogenics performance, flexibility and reliability solved with Nexans CRYOFLEX® transfer lines

- Flexible, small diameter, low heat loss, heavy duty, maintenance free

- Ability to make continuous long length, without joints for the cryostats - key to success

- Manufacturing process instrumental to successfully solution the insulation tear devastating to cable performance (wire to wire or wire to ground).

Joint-free cryogenics transfer lines meet these critical application requirements. Nexans can guarantee no burrs or weld slag from internal cryostat joints (no joints).

“ Conscious of their capabilities, Nexans teams were able to provide the most effective solutions and commit to deliver customized solutions aimed at this very specific application. ”

Since decades, Nexans cryogenics engineering capabilities has enabled various industries (LN2, LH2, Health Care) to benefit from tailored made cryogenics transfer lines and cryostats manufactured under the most highest quality standards.

Nexans’ solid proposal and their ability to come up with customised solution tailored to specific application were crucial in this project and reinforced an already strong partnership with AMSC with regards cryogenics systems.

Our websites

Select your country to find our products and solutions

-

Africa

- Africa

- Ghana

- Ivory Coast

- Morocco

- North West Africa

- Americas

- Asia

- Europe

- Oceania