- Markets

- Products

- Services

- News

- Tools & Resources

- About Nexans

- Search

- Contact us

- Compare

- Sign in

Building

Electrical installations: understand the reaction and fire resistance of cables

Nov 12, 2025

Electrical cables that do not spread fire

There are two important concepts to consider in fire safety, reaction and resistance to fire. To put it simply, the reaction to fire is how an object, a material, a cable will react when exposed to a heat source (a flame for example). Here, the component, the cable is considered passive.

On the other hand, in fire resistance, the cable is active. It must continue to operate and ensure the electrical continuity of safety devices even in extreme conditions, at temperatures sometimes above 1000°C. Here we will deal with the reaction to fire aspect.

How does a fire develop?

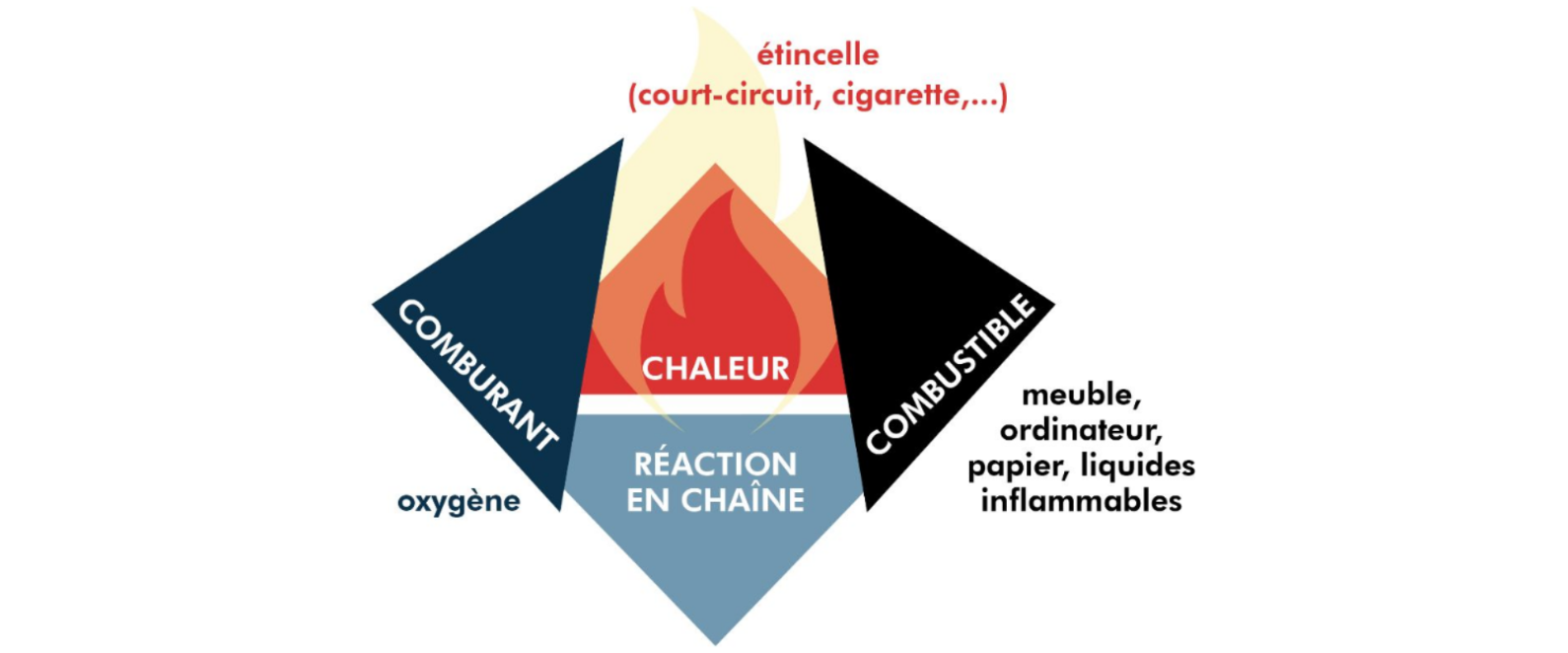

The fire triangle : For a fire to start, three elements must be present simultaneously.

Oxygen: always available in the air at a rate of 21%

Fuel: which is also available in massive quantities in our homes

A trigger: for example, an electric arc generated by an electrical fault, or an external source such as a primary focus due to a criminal fire.

This is the principle of the fire triangle. As soon as these 3 elements are combined, the fire can start. He only wants one thing: to grow, to grow while feeding on the surrounding fuel.

A very fast development

In this case, it is generally said that one minute after the start of a fire, only one glass of water is enough to extinguish it. After two minutes, a bucket of water is needed, and after three minutes, the fire is out of control. Only firefighters or well-trained people can act to contain the disaster. With this in mind, it is crucial to have the possibility of evacuating from the building as quickly as possible.

Moreover, during the combustion of combustible materials, the fire produces additional heat that promotes its propagation. During the process of material degradation, opaque and harmful fumes are also released. And this is the main risk for people. The fumes quickly reduce visibility in the area, decreasing the chances of evacuation of people. Moreover, these fumes can be acidic and/or harmful. This then affects people’s chances of escaping, also impacting their health in the medium or long term.

What role do fire protection cables play in fire safety?

The cable must not react to fire

It must be understood that in buildings, cables are everywhere and in massive quantities. They walk in all spaces often being invisible. It is also estimated that between 200 and 300kg of cables need to be installed for a surface area of 100m 2.

Therefore, when a fire starts, the cable, if exposed, must not react by remaining as inert as possible. Otherwise, the fire will spread by following its path all along the building. With a low-performance solution, such as R2V cables, it is demonstrated that the fire exceeds in less than 3 minutes the first floor of a building and then spreads even more quickly to the rest of the structures. On the other hand, Nexans' LFH (Low Fire Hazard) ranges limit smoke emissions and fire growth by 5 to 10 times.

The reaction to fire cables at Nexans

Nexans offers cables with high performance in reaction to fire with limited propagation, low heat release and low smoke production. They can also limit the generation of flaming droplets during the combustion of plastic materials, thus avoiding secondary fires and also the risk for firefighters of receiving flaming objects falling from ceilings. They are known under the brand Nexans Protect.

How to distinguish a performing cable?

The CPR (Regulation for Construction Products) has been applied since June 2017 in all countries of the European Union. This harmonized system, including a common language and common methods for testing and certifying products, allows all EU countries to have the same interpretation of a fire reaction performance.

The codes of the Euroclasses

This system is based on Euroclasses. It results in a marking that can be found on the cable and on its DDP (Declaration of Performance).

The marking is based on a precise set of codes:

A first: B2ca, Cca, Dca, Eca translates the performance in non-propagation of fire, flame and heat release. The most efficient being the B2ca.

A second: s1a, s1b, s1, s2, s3. It indicates the potential for smoke release. s1a being reputed as the best performance.

A third: d0, d1, d2 which characterizes the potential of the cable to generate secondary fire outbreaks by the fall of inflamed particles.

One last: a1, a2, a3 indicates the corrosive potential of the fumes. This parameter makes it possible to evaluate the ability of people to leave a building, and also to generate the corrosion of elements affected by fumes. The performances a1 and a2 prohibit the implementation of PVC cables (R2V, H07V-U...)

Fire-resistant cables

The reaction to fire is the way an object, a material, a cable for example, reacts when exposed to a heat source. It is a question of characterizing the potential for flame propagation, fire, the heat emitted as well as the amount of smoke released and potentially their corrosive or even harmful nature.

Fire resistance is another property. Here the cable is considered an active component. It must allow the electrical integrity of fire safety systems to be maintained under extreme conditions, at very high temperatures, sometimes above 1,000°C, for a minimum duration given in national regulations. Depending on the countries, the applications, this time can be very different. In France, the fire resistance is at least 65 minutes, which corresponds to temperature conditions of at least 920°C.

How to recognize fire-resistant electrical cables?

Fire-resistant cables are recognizable by their color, usually orange, and can be confused with data cables, which are the same color. To remove the doubt, one must refer to the marking. If the indication CR1 appears, the cable is well resistant to fire.

In which cases to use them?

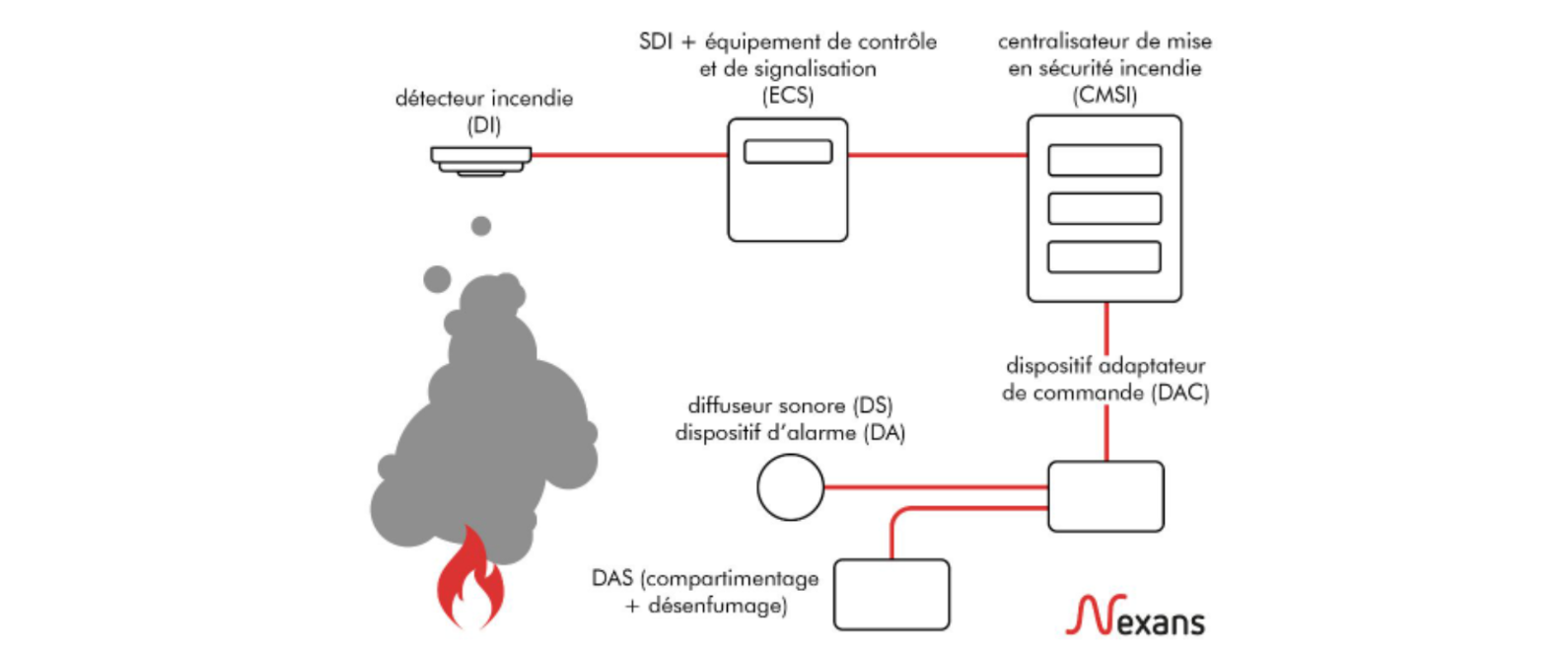

There are several families of fire-resistant cables. We first have the so-called 'telecommunication' cables. They carry a "weak current". These cables are mainly intended to be used in electrical circuits for fire safety systems, which can be found in IGH, ERP, and ERT. They allow in particular to connect an ECS (Central Safety Equipment), a CMSI (fire safety centralizer) to smoke detectors, to warning devices such as sound diffusers. They are essential to ensure the evacuation of people in the best conditions. However, there is no regulatory obligation to use them along the entire length of the circuit. However, this can be recommended to ensure continuity of information even when the fire is raging.

Then, there is another range allowing the supply of safety devices requiring more power such as security lighting, smoke extraction equipment, water recirculation pumps...

For this range, a point is sometimes overlooked when sizing the installation. It is about the strong increase of the resistance of copper with the rise of temperature in the fire. Between 90°C (the operating temperature of the cable in normal condition) and 920°C (the operating temperature in fire condition), this resistance is multiplied by 4. It is therefore essential to pay attention to it, especially for equipment that cannot withstand a voltage drop to operate properly. Tools such as EasyCalc allow adjusting the design of the cable to be installed according to the instructions given on the technical sheet of the equipment to be connected and the configuration of the building.

Other specificities of fire-resistant cables

It is important to note that fire-resistant cables also have very good performance in terms of reaction to fire. They are also classified in the best categories. In France, they are C1, which demonstrates their very low contribution to the spread of the fire. They are also classified as having low smoke emissions (IEC/EN 61034-2), which is non-corrosive (IEC/EN60754-2).

It should be noted that the French classification system (CR1-C1) is expected to disappear in the medium term. It will be replaced by a harmonized European system, the Euroclasses. It is here suggested for France a Pca60 category in terms of fire resistance and this will need to be validated by the French fire regulator, which is the only one to have this prerogative.

FAQ

What’s the difference between reaction to fire and fire resistance for a cable?

Reaction to fire describes how a cable behaves when exposed to a flame (fire spread, heat release, smoke and droplets). Fire resistance refers to the cable’s ability to keep operating during a fire, maintaining electrical continuity for safety systems.

How does a fire develop in a building?

A fire starts when three elements come together: oxygen, fuel and an ignition source (an electrical arc, a fault, or an external ignition source). Once it starts, it spreads quickly by feeding on surrounding materials.

Why are fumes a major risk during a fire?

Smoke rapidly reduces visibility, makes evacuation harder and can be harmful or corrosive. Limiting smoke release directly improves occupant safety and supports emergency response.

Why do cables play a key role in fire spread?

Cables are installed in large quantities throughout a building. If they react strongly to fire, they can promote flame spread along cable routes and accelerate fire growth across areas.

What is an “LFH” (Low Fire Hazard) cable and what is it used for?

An LFH cable is designed to reduce its contribution to fire and limit smoke emissions. The goal is to slow fire development and improve evacuation conditions.

How can you identify a high-performing reaction-to-fire cable?

Check its CPR (Euroclass) rating on the cable marking and on the Declaration of Performance (DoP). Euroclasses allow objective comparison based on harmonised test methods.

How do you read a cable Euroclass (e.g., Cca-s1,d2,a1)?

The class (Cca, s2, d2, a2) summarises reaction-to-fire performance. “s” indicates smoke level, “d” refers to flaming droplets, and “a” relates to the acidity/corrosivity of fumes.

Why do flaming droplets matter?

They can cause secondary fires when falling onto surfaces and create additional risks for occupants and emergency responders.

What are fire-resistant cables and what are they used for?

Fire-resistant cables must maintain electrical integrity for safety circuits (alarms, smoke extraction, emergency lighting, etc.) during a fire, at very high temperatures, for a minimum duration defined by national regulations.

How can you recognise fire-resistant cables on site?

Colour (often orange and increasingly dark blue in some markets) can be a clue, but only the marking is definitive. For example, “CR1” is commonly used to identify fire-resistant cables in certain market practices.

When should fire-resistant cables be used?

For “low-current” safety circuits (detection, alarms, fire safety control systems, warning devices) and for powering higher-demand safety equipment (emergency lighting, smoke extraction, pumps, etc.), depending on building requirements and project design.

What Euroclass level is mandatory for ERP and high-rise buildings (IGH) after May 23, 2025?

A minimum Euroclass of Cca-s2,d2,a2 is mandatory for any building permit or works authorisation filed after May 23, 2025 for ERP (buildings open to the public) and IGH (high-rise buildings).

Why is sizing critical for fire-resistant cables?

During a fire, copper resistance increases sharply with temperature, which can lead to voltage drop. This must be considered to ensure safety equipment keeps operating properly, especially over long cable runs.

Our websites

Select your country to find our products and solutions

-

Africa

- Africa

- Ghana

- Ivory Coast

- Morocco

- North West Africa

- Americas

- Asia

- Europe

- Oceania